Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

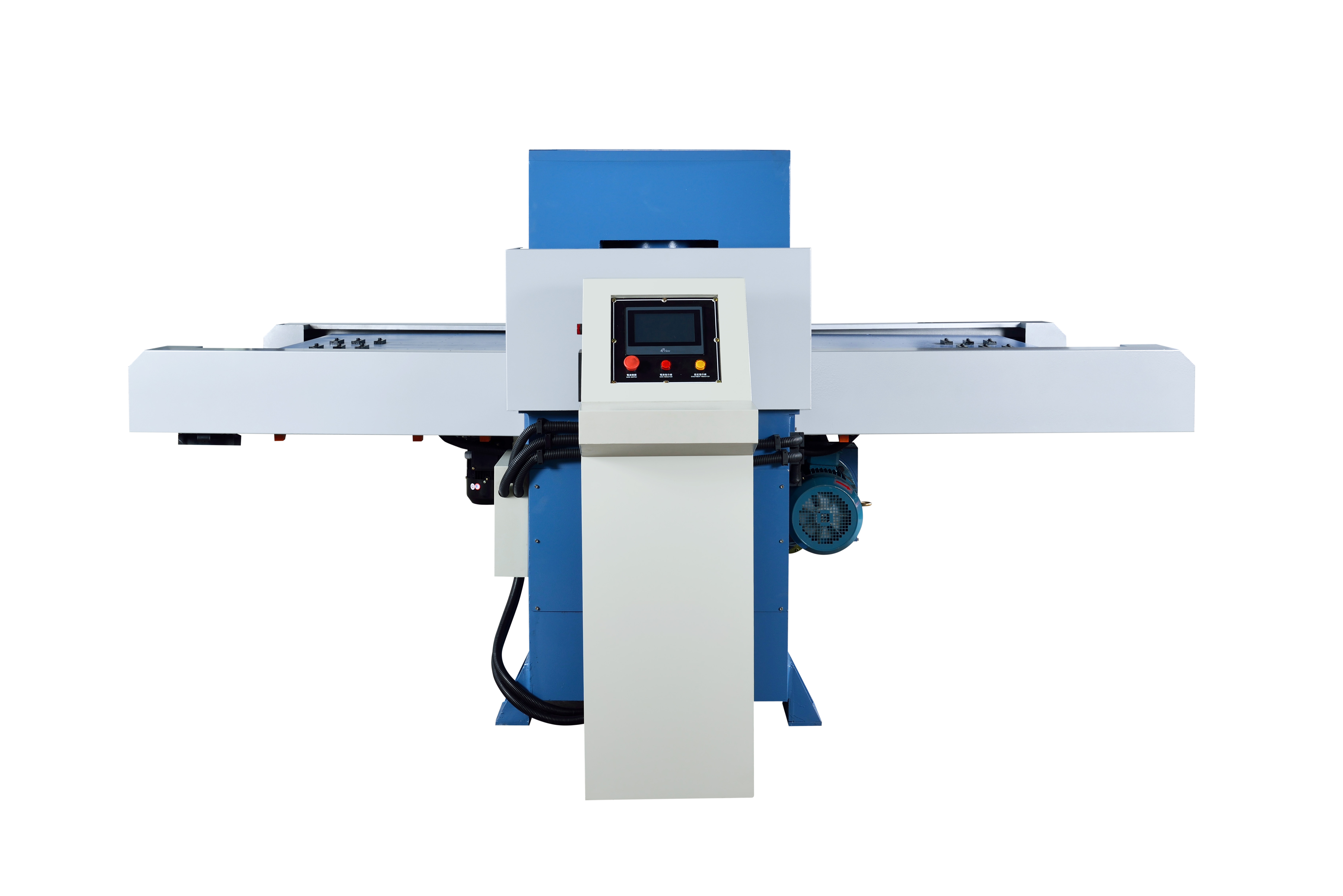

The cutting machine has stable pressure, so it can cut materials with high precision, ensuring accurate cuts and reducing material waste, which makes it stand for many years. It can also cut materials at a much faster rate than traditional cutting methods, increasing productivity and reducing lead times. Whatever the material is, it can cut a wide range of materials, including metals, plastics, and fabrics, making them suitable for a variety of applications.

High Efficiency:

The machine can cut materials with high precision, and ensures accurate cuts and reduces material waste. The products made are consistent cuts, ensuring that each piece is identical in size and shape, which is important for applications such as mass production. The way to cut can be automated, which greatly reduces the need for manual labor and increases the efficiency.

Wide application:

Cutting machines can cut a wide kind of materials, including plastics, fabrics, and composites, which make it for various of applications. It can be customized to meet specific cutting requirements, which can well meet your requirement. Its safety features protect operators and prevent accidents, making them a safer option than traditional cutting methods. It is cost-effective for cutting a wide range of materials, well reducing material waste.

Durable:

The cutting machines are made of high-quality materials, such as steel and aluminum, which are strong and durable. It is also equipped with advanced technology, such as CNC controls and laser cutting systems, which are designed to operate efficiently and reliably. It has safety protector that protects the machine and the operator, reducing the risk of damage and increasing durability.

Application:

Notice of the Cutting Machine?

1. After the machine is installed, it is necessary to ensure that the safety protection devices are complete, and to make sure of the lines and pipelines are complete.

2. When repairing, adjusting, refueling, wiping and inspecting the machine, the power supply must be cut off first to avoid danger.

3. Before turning on the machine, pay attention to the surrounding environment to see if there are people working under the machine.

4. During working, it is not allowed to place any irrelevant items such as tools on the self-priming pump.